Click on the categories to display the questions. Click on the questions to display answer. (Click to display all close all)

Atmosphere control  Delivery and Shipping

Delivery and Shipping  Electrode contact assemblies, springs, gas tubes, etc.

Electrode contact assemblies, springs, gas tubes, etc.  Furnaces

Furnaces  ProboStat - General

ProboStat - General  ProboStat - Maintenance

ProboStat - Maintenance  ProGasMix

ProGasMix  Samples

Samples  Sealing

Sealing  Support

Support  The company

The company  Thermocouples and temperature control

Thermocouples and temperature control  Troubleshooting - ProboStat

Troubleshooting - ProboStat  Visiting Oslo

Visiting Oslo

|

|

How can I repair a Pt electrode contact?

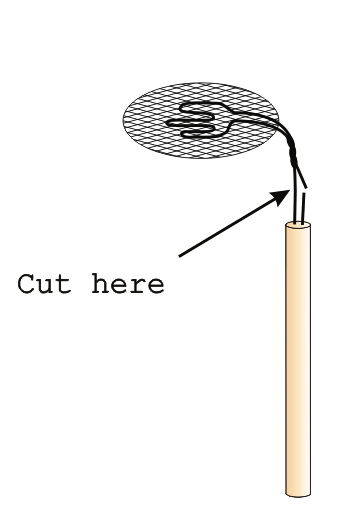

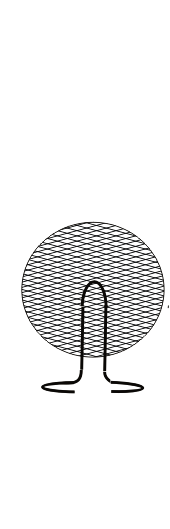

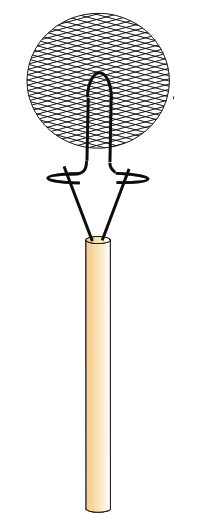

Let us consider three possible cases: 1. An electrode is rigid and brittle after measurements. Platinum wires may often be revitalized by glowing in air. This drives out hydrogen and some other gases, re-crystallizes wires, and gives them much of their softness and strength back. Then: 1) Suspend the wire freely from a clip on e.g. a stand of some kind. Preferably clip a small weight onto the end. 2) Heat it until yellow glow by a gas burner. By this it should soften and straighten. 2. A Pt net of a “hand” electrode contact is damaged or contaminated. Sometimes the Pt net may sinter to a sample or sample electrode during high temperature measurements. In order to separate the sample, you can use a scalpel or slight force, but in that way risking damaging the electrode contact. The Pt net can get contaminated, for example by melted gold ring. It also can get strongly deformed or peeled off the “hand” due to rough handling. Then, if you need to replace the Pt net: 1) Gently remove the net from the “hand”. 2) Place electrode contact “hand” area between (clean) steel pistons, such that at least 1.5 cm from the centre of the electrode formation will be pressed. 3) Place a new Pt net on the "hand". 4) Press at 5 metric tons in a hydraulic press for a few seconds. 5) Heat pressed area until yellow glow to soften the Pt. You may also replace a top part of the “hand” electrode contact as a whole. Please, see below (3). 3. One of Pt wires of the “hand” electrode contact is broken. This may happen because of the electrode contact mechanical ageing, or rough handling. This can be fixed using a short piece of Pt wire, but, in most cases, the top part needs to be replaced. Then (see figures): 1) Cut off destroyed top part. 2) Use GP2N# as a replacement part. 3) Place electrode contacts in the grip (also see Figure 8-2 in the ProboStat Manual) and fasten using pliers. 4) Check resistance. Pt electrode should give less than 0.5 ohm when contacted by the probe tips of a multimeter 1 cm apart. Sometimes one cannot succeed with sufficient fastening GP2N# by pliers. Then one can twist wires, weld or put a drop of Pt ink on the connection point and anneal it. Check resistance. Repaired electrode contact can normally be used for all measurements except from current collection in a fuel cell test. For the fuel cell test we recommend to use a brand new electrode contact.

You can always also buy new electrode contacts from NORECS. |